The promise of silk biomaterials: An opportunity to expand the performance envelope of transient medical products

A perspective article by Dr Premnath Venugopalan, Co-founder and Chair, Serigen Mediproducts

The question

I am often asked why we chose to focus on silk biomaterials instead of any other biomaterial for developing bioabsorbable medical products. This is a fair question and let me try and answer it here.

A primer on materials-based biomedical products

Biomedical products comprise a wide range of products serving many different purposes. A subset of these products are materials-based supplies used by clinicians and surgeons to perform certain permanent or temporary functions relating to healing, augmentation, repair and rehabilitation.

Examples include:

Category A — Materials-based products used for permanent purposes: Knee and hip replacements, rods and plates inserted in patients after accidents, volume filling implants for craniotomy-maxillo-facial surgery, breast implants, hernia meshes, etc.

Category B — Materials-based products used for temporary purposes: Wound healing products, implants used for augmentation or temporary support like degradable fixation devices, tissue engineering products, degradable plastic surgery products, etc.

Category B above imposes very interesting challenges for material scientists working to develop medical products because these products are expected to be transient in nature and should safely disappear after performing their temporary purpose.

Category B products usually serve the following functions:

- Create conditions for natural healing

- Improved (accelerated and/or better quality) healing and repair

- Augmentation and support of body parts/ functions

- Regeneration of tissues

Typical requirements of Category B products include:

- Acceptance by body: no rejection; bio-integration

- Product and its degradation products are safe and non-toxic

- Predictable degradation/disappearance within the body

- Other requirements as per the clinical use case and function being performed (for example, a fixation device will need to have certain mechanical properties, a wound healing product may need mechanisms to manage moisture levels, tissue engineering products may need porosity for cell ingress, a plastic surgery product may need mechanical compliance and required shape-ability, etc)

A variety of materials have been explored and used for Category B products, including:

- Human patient’s own tissues (autografts)

- Tissues taken from another human or human cadaver (allografts)

- Tissues taken from another animal (xenografts)

- Materials extracted and purified from natural sources

- Synthetic materials

Autografts are a great option in many use cases. However, they need to be extracted from the same patient via an extra surgery and can result in damage to the extraction site. Depending upon the volumes needed and the patient’s overall health, autografts may not be an option at all.

Allografts require maintenance of human tissue banks and there is a chance of rejection and/or infections. Xenografts run the risk of transmission of animal diseases and being rejected by the human body. Some patients will also have religious/ethical reasons to avoid certain xenografts.

Autografts, allografts, and xenografts are typically used in the form in which they are collected (with some sterilization, etc, as needed). However, they do not offer a lot of flexibility in terms of processing for tailoring structures/ properties for specific applications.

The above shortcomings are the reasons why purified materials from natural and synthetic sources are attractive options for Category B medical products mentioned above.

Some key benefits of purified materials from natural and synthetic sources include:

- No constraints or uncertainties or delays on supply; Easy availability

- Usually no need for very specialised handling/preservation of samples

- Ability to process into various structures, shapes and forms

- No risks of infections or transmission of certain diseases (including by pathogenic proteins)

Examples of purified materials from natural or synthetic sources commonly used are:

- Purified materials from natural sources: Collagen, Chitin, Silk proteins, Alginates, etc

- Synthetic materials: Polylactic acid, PCL, PLGA, degradable polyurethane, beta-TCP, CaSO4, bioglass, etc

As mentioned above, silk proteins are purified materials from natural sources that fall under Category B medical products.

What is unique about silk proteins?

From the above list, silk proteins are particularly special because:

- Silk has a long clinical history of use as sutures and is known for its safety

- It is a natural polymer that easily integrates with the human body

- It is a protein that will break down into natural amino acids that the body already knows how to deal with

- It is biodegradable with levers available to tune the rate of degradation

- There are many ways to get a wide range of structural features (like porosity and pore shape) and mechanical properties (from soft to hard)

- They are amenable to multiple processing techniques to create structure and shape.

Silk can be processed using a variety of methods including:

- Casting into films

- Fiber spinning, weaving

- 3D printing

- Electro spinning

- Paper making

- Molding

Silk proteins can also be mixed with other materials to make blends and composites as needed.

Silk proteins can be processed into a variety of shapes/forms:

- Films and sheets

- Mats

- Fibers

- Solid blocks

- Porous molded shapes (discs, cylinders, wedges)

- Foams

- Microspheres

- Granules

- Putties

But most importantly, silk proteins allow for levers/ handles to tune certain very important properties of degradable medical products, such as:

- Biodegradation rate or dissolution rate (tunable from days to weeks to months)

- Pore structure, pore surface and porosity suitable for cell migration and proliferation (porosity tunable from 0-90%)

- Mechanical properties (tunable from soft foams to cortical bone-like hard materials)

- If required, silk proteins can also be chemically modified with pendant groups

This enormous range and versatility is what makes silk biomaterials special! To my knowledge, no other single material platform has the same extent of versatility. The consequence of this is that one single material platform (that of silk biomaterials) can be used (in principle) for more than 75% of medical applications that need biodegradation!

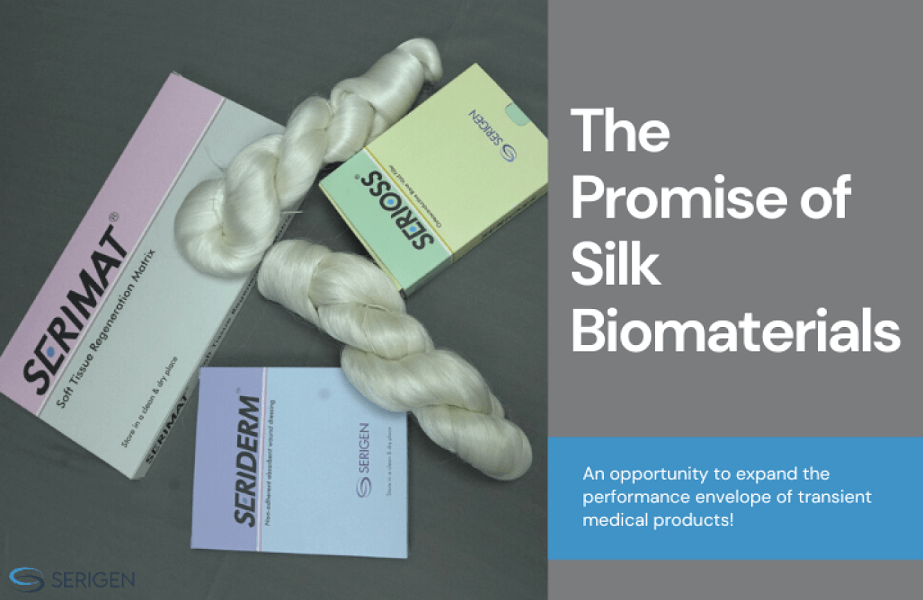

Serigen: The tissue engineering company leveraging silk proteins

Serigen takes its name from Seri (for silk) and Regeneration! Serigen focuses on using natural and safe silk proteins as raw materials to develop medical products that can help heal or regenerate human tissues damaged or lost in injuries and surgeries. While the use of silk proteins in medical products is well established, the Serigen team has learned to organise and arrange these proteins in new structures, forms and shapes that are tailored to enhance tissue repair and regeneration. The Serigen team applies the central paradigm of material science (that is structure-property relationships) to invent powerful new products using silk biomaterials!

In our studies so far, we have already been able to demonstrate outstanding results even for challenging clinical needs such as:

— Healing of even difficult-to-heal wounds and ulcers like diabetic ulcers, bed sores, etc

— Bone regeneration for large cavities

It is so exciting and satisfying to see patients benefiting from silk-based biomedical products. We are grateful at Serigen to be able to make it possible. It inspires and motivates us to work harder every day!

Author Bio – Dr Premnath Venugopalan is Co-founder and Chair at Serigen Mediproducts. He holds a PhD from MIT USA and is a trained chemical engineer from IIT-Bombay (Distinguished Alumnus, 2022), along with being a Chevening Technology Enterprise Scholar in Cambridge, UK. He is also Head, NCL Innovations at CSIR-NCL and Founder Director at Venture Center.

A perspective article by Dr Premnath Venugopalan, Co-founder and Chair, Serigen Mediproducts

The question

I am often asked why we chose to focus on silk biomaterials instead of any other biomaterial for developing bioabsorbable medical products. This is a fair question and let me try and answer it here.

A primer on materials-based biomedical products

Biomedical products comprise a wide range of products serving many different purposes. A subset of these products are materials-based supplies used by clinicians and surgeons to perform certain permanent or temporary functions relating to healing, augmentation, repair and rehabilitation.

Examples include:

Category A — Materials-based products used for permanent purposes: Knee and hip replacements, rods and plates inserted in patients after accidents, volume filling implants for craniotomy-maxillo-facial surgery, breast implants, hernia meshes, etc.

Category B — Materials-based products used for temporary purposes: Wound healing products, implants used for augmentation or temporary support like degradable fixation devices, tissue engineering products, degradable plastic surgery products, etc.

Category B above imposes very interesting challenges for material scientists working to develop medical products because these products are expected to be transient in nature and should safely disappear after performing their temporary purpose.

Category B products usually serve the following functions:

- Create conditions for natural healing

- Improved (accelerated and/or better quality) healing and repair

- Augmentation and support of body parts/ functions

- Regeneration of tissues

Typical requirements of Category B products include:

- Acceptance by body: no rejection; bio-integration

- Product and its degradation products are safe and non-toxic

- Predictable degradation/disappearance within the body

- Other requirements as per the clinical use case and function being performed (for example, a fixation device will need to have certain mechanical properties, a wound healing product may need mechanisms to manage moisture levels, tissue engineering products may need porosity for cell ingress, a plastic surgery product may need mechanical compliance and required shape-ability, etc)

A variety of materials have been explored and used for Category B products, including:

- Human patient’s own tissues (autografts)

- Tissues taken from another human or human cadaver (allografts)

- Tissues taken from another animal (xenografts)

- Materials extracted and purified from natural sources

- Synthetic materials

Autografts are a great option in many use cases. However, they need to be extracted from the same patient via an extra surgery and can result in damage to the extraction site. Depending upon the volumes needed and the patient’s overall health, autografts may not be an option at all.

Allografts require maintenance of human tissue banks and there is a chance of rejection and/or infections. Xenografts run the risk of transmission of animal diseases and being rejected by the human body. Some patients will also have religious/ethical reasons to avoid certain xenografts.

Autografts, allografts, and xenografts are typically used in the form in which they are collected (with some sterilization, etc, as needed). However, they do not offer a lot of flexibility in terms of processing for tailoring structures/ properties for specific applications.

The above shortcomings are the reasons why purified materials from natural and synthetic sources are attractive options for Category B medical products mentioned above.

Some key benefits of purified materials from natural and synthetic sources include:

- No constraints or uncertainties or delays on supply; Easy availability

- Usually no need for very specialised handling/preservation of samples

- Ability to process into various structures, shapes and forms

- No risks of infections or transmission of certain diseases (including by pathogenic proteins)

Examples of purified materials from natural or synthetic sources commonly used are:

- Purified materials from natural sources: Collagen, Chitin, Silk proteins, Alginates, etc

- Synthetic materials: Polylactic acid, PCL, PLGA, degradable polyurethane, beta-TCP, CaSO4, bioglass, etc

As mentioned above, silk proteins are purified materials from natural sources that fall under Category B medical products.

What is unique about silk proteins?

From the above list, silk proteins are particularly special because:

- Silk has a long clinical history of use as sutures and is known for its safety

- It is a natural polymer that easily integrates with the human body

- It is a protein that will break down into natural amino acids that the body already knows how to deal with

- It is biodegradable with levers available to tune the rate of degradation

- There are many ways to get a wide range of structural features (like porosity and pore shape) and mechanical properties (from soft to hard)

- They are amenable to multiple processing techniques to create structure and shape.

Silk can be processed using a variety of methods including:

- Casting into films

- Fiber spinning, weaving

- 3D printing

- Electro spinning

- Paper making

- Molding

Silk proteins can also be mixed with other materials to make blends and composites as needed.

Silk proteins can be processed into a variety of shapes/forms:

- Films and sheets

- Mats

- Fibers

- Solid blocks

- Porous molded shapes (discs, cylinders, wedges)

- Foams

- Microspheres

- Granules

- Putties

But most importantly, silk proteins allow for levers/ handles to tune certain very important properties of degradable medical products, such as:

- Biodegradation rate or dissolution rate (tunable from days to weeks to months)

- Pore structure, pore surface and porosity suitable for cell migration and proliferation (porosity tunable from 0-90%)

- Mechanical properties (tunable from soft foams to cortical bone-like hard materials)

- If required, silk proteins can also be chemically modified with pendant groups

This enormous range and versatility is what makes silk biomaterials special! To my knowledge, no other single material platform has the same extent of versatility. The consequence of this is that one single material platform (that of silk biomaterials) can be used (in principle) for more than 75% of medical applications that need biodegradation!

Serigen: The tissue engineering company leveraging silk proteins

Serigen takes its name from Seri (for silk) and Regeneration! Serigen focuses on using natural and safe silk proteins as raw materials to develop medical products that can help heal or regenerate human tissues damaged or lost in injuries and surgeries. While the use of silk proteins in medical products is well established, the Serigen team has learned to organise and arrange these proteins in new structures, forms and shapes that are tailored to enhance tissue repair and regeneration. The Serigen team applies the central paradigm of material science (that is structure-property relationships) to invent powerful new products using silk biomaterials!

In our studies so far, we have already been able to demonstrate outstanding results even for challenging clinical needs such as:

— Healing of even difficult-to-heal wounds and ulcers like diabetic ulcers, bed sores, etc

— Bone regeneration for large cavities

It is so exciting and satisfying to see patients benefiting from silk-based biomedical products. We are grateful at Serigen to be able to make it possible. It inspires and motivates us to work harder every day!

Author Bio – Dr Premnath Venugopalan is Co-founder and Chair at Serigen Mediproducts. He holds a PhD from MIT USA and is a trained chemical engineer from IIT-Bombay (Distinguished Alumnus, 2022), along with being a Chevening Technology Enterprise Scholar in Cambridge, UK. He is also Head, NCL Innovations at CSIR-NCL and Founder Director at Venture Center.