Moisture Vapour Transmission Rate (MVTR) - A Critical Parameter of Advanced Dressings in Moist Wound Healing

Wound healing is a complex and dynamic process that includes various stages like haemostasis, inflammation, proliferation, and re-modelling. These stages work in an orchestrated manner to repair damaged tissue and restore function. Classic wound dressings for exuding wounds must remain in close contact with the wound and be non-adherent to the wound surface to prevent damage to the delicate wound healing layer. Furthermore, they must have optimum absorption capacity with excellent Moisture Vapour Transmission Rate (MVTR) to remove excess fluid and maintain a moist environment that promotes optimal healing.

The Benefits Of A Moist Wound Environment For Wound Healing

Exuding skin wounds are a major concern in health care. To address these wounds, moist wound healing has been practised since at least the seventh century (Paulus of Aegina). In 1850, Langenbeck used wet treatment for surgical wounds, and eight years later, Passavant reported on wet (immersion in a bathtub) treatment of burns. Like other tissues, skin tissue is capable of self-regeneration. However, different types of exuding wounds like diabetic wounds, second-degree burn wounds, bed sores, and large traumatic wounds fail to self-heal and require intervention in the form of wound dressings that accelerate the healing process. The benefits of a moist wound environment are multifaceted, leading to faster and more effective healing. Firstly, the absence of an eschar or dead tissue that forms over healthy skin, allows for quicker wound closure, saving time and energy. Secondly, the moist environment enables epithelial cells to migrate and re-epithelialize the wound more efficiently, as keratinocytes can rapidly cover the wound surface without the need to navigate through a dry crust. Moreover, the moist environment eliminates the need for forceful removal of dry dressings, thereby reducing pain for patients. Moist environment also facilitates effective nutrient transport for cells to proliferate and differentiate.

While a moist environment creates conditions conducive to microbial growth, yet surprisingly, wounds treated with moist dressings have been found to have lower infection rates compared to those treated with dry dressings. Overall, the use of moist dressings can significantly improve wound healing outcomes by reducing pain, promoting tissue regeneration, and limiting the risk of infection.

What Is Moisture Vapour Transmission In Wound Dressings And How Does It Promote Better Healing?

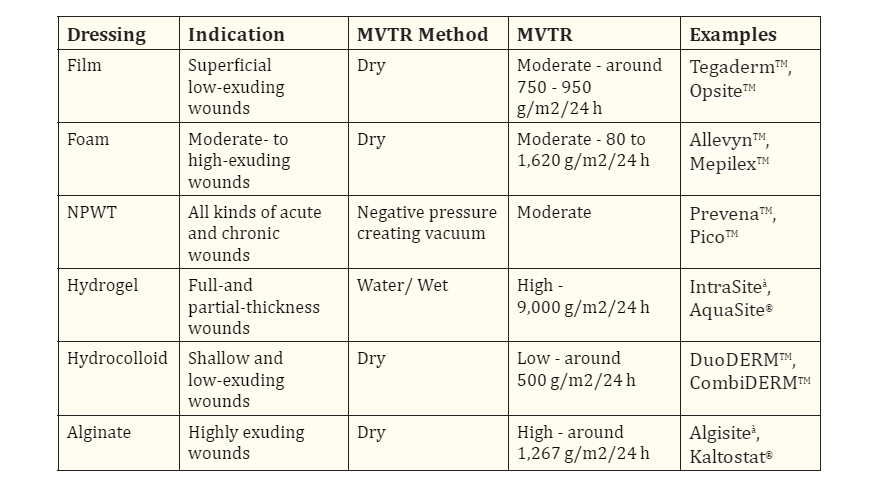

Moist wound dressings can be in the form of films, foams, hydrocolloid dressings, hydrogels, alginate dressings, and NPWT dressings. There is no one dressing that fits all wound types. Moreover, as the healing of a wound progresses and the amount of exudate decreases, one single dressing may not be optimal for the different phases of healing.

Table 1. Types of dressings, MVTR range and Examples

.

|

Dressing |

Indication |

MVTR Method |

MVTR |

Examples |

|

Film |

Superficial low-exuding wounds |

Dry |

Moderate – around 750 – 950 g/m2/24 h |

TegadermTM, OpsiteTM |

|

Foam |

Moderate- to high-exuding wounds |

Dry |

Moderate – 80 to 1,620 g/m2/24 h |

AllevynTM, MepilexTM |

|

NPWT |

All kinds of acute and chronic wounds |

Negative pressure creating vacuum |

Moderate |

PrevenaTM, PicoTM |

|

Hydrogel |

Full-and partial-thickness wounds |

Water/ Wet |

High – 9,000 g/m2/24 h |

IntraSiteà, AquaSite® |

|

Hydrocolloid |

Shallow and low-exuding wounds |

Dry |

Low – around 500 g/m2/24 h |

DuoDERMTM, CombiDERMTM |

|

Alginate |

Highly exuding wounds |

Dry |

High – around 1,267 g/m2/24 h |

Algisiteà, Kaltostat® |

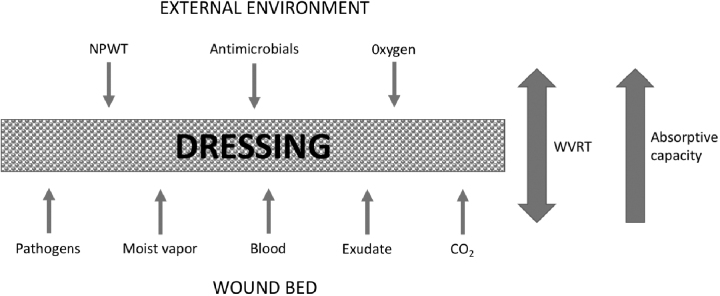

The moist dressing’s ability to transmit water vapour, known as Moisture Vapour Transmission Rate (MVTR), is a crucial physical characteristic that enables effective wound healing. MVTR is the steady state at which water vapour permeates the dressing. It is measured using two methods: the desiccant method (ASTM E-96 Test) and the water method. In the desiccant method, a cup assembly is placed in a dry incubator with controlled temperature and airflow. Periodic manual weighing of the cup measures the amount of water lost over time, determining the MVTR. The test cups are placed upright for low moisture contact. [Fig 2.]

In the water method, a dish is filled with water and the dressing is sealed on top, then placed in an environment with low humidity. The amount of water vapour transferred from the dish during the test period is measured by weighing the dish.

To ensure accuracy and consistency, both methods are considered in the standard test method for MVTR, which takes into account the differences in results between the two procedures. For the desiccant method, the MVTRs of the dressings varies from 80 to 1620 g/m2/24 h.

The Moisture Vapour Transmission Rate (MVTR) of a wound dressing is a crucial factor in maintaining the optimal level of hydration for the wound. A dressing with very high MVTR leads to wound desiccation/drying while a very low MVTR will lead to complications like infection, maceration, etc. Therefore, finding a dressing with an optimal MVTR is essential to prevent desiccation or excessive fluid accumulation. For instance, an MVTR of 800 – 1000 g/m2/24h has been suggested to provide an adequate level of moisture without risking desiccation. However, different wounds require different levels of moisture management.

How Does Seriderm Provide An Optimal Moist Wound Healing Environment?

Seriderm/Seriderm Ag have an MVTR of 800 ± 100 g/m2/24 h to provide an optimal moist environment locally to promote wound healing.

Seriderm/Seriderm Ag is an advanced wound dressing completely made out of a natural polymer of Silk proteins. Seriderm is a non-adherent and absorbent silk protein-based dressing that offers optimal moisture management at the wound site by absorbing exudate and maintaining ideal moisture levels for faster healing. Additionally, Seriderm’s novel composition improves vasculature and granulation tissue formation. With these unique advantages, Seriderm promotes faster healing of a wide range of wounds, including chronic, non-healing wounds such as diabetic ulcers, second-degree burns, pressure ulcers, and surgical wounds. Additionally, Seriderm Ag combines the healing power of Seriderm with the antimicrobial action of Silver ions for management of infected wounds.

Seriderm dressing has a range of MVTR of 800-1000g/m2/24 h, which is suggested to provide an adequate level of moisture without risking desiccation. Our dressings have adequate absorptive capacity which can be applied to moderately exuding wounds.

Conclusion

Wound dressings play a crucial role in creating and maintaining a moist environment, essential for optimal wound healing. Seriderm/Seriderm Ag dressings have the ability to transmit water vapour, absorb excess fluid, and maintain antimicrobial properties. Additionally, these dressings have integrity and absorptive capacity that maximises their wear time by matching the wound’s fluid production to prevent accumulation of exudate or dehydration. This allows for a controlled moist environment that gives non-adherence, reduces pain during dressing changes, prevents scarring, and supports tissue growth and repair for better wound healing.

References

[1] Testing dressings and wound management materials S. T. THOMAS

[2] Nuutila K, Eriksson E. Moist Wound Healing with Commonly Available Dressings. Adv Wound Care (New Rochelle). 2021 Dec;10(12):685-698. doi: 10.1089/wound.2020.1232. Epub 2021 Feb 11. PMID: 32870777; PMCID: PMC8568799.

[3] Jones V, Grey JE, Harding KG. Wound dressings. BMJ. 2006 Apr 1;332(7544):777-80. doi: 10.1136/bmj.332.7544.777. PMID: 16575081; PMCID: PMC1420733.

[4] ASTM. 1986. “Standard Test Methods for Water Vapour Transmission of Materials.” Annual Book of ASTM Standards, 15(9):833-842.

[5] Zehrer CL, Holm D, Solfest SE, Walters SA. A comparison of the in vitro moisture vapour transmission rate and in vivo fluid-handling capacity of six adhesive foam dressings to a newly reformulated adhesive foam dressing. Int Wound J. 2014 Dec;11(6):681-90. doi: 10.1111/iwj.12030. Epub 2013 Jan 30. PMID: 23362795; PMCID: PMC7951035.

Author Bio – Jaya Verma is a Production Engineer at Serigen Mediproducts. She holds a B.Tech in Polymer Specialization from MIT-WPU, Pune and has 2 years of professional experience in the production of wound dressings.

Wound healing is a complex and dynamic process that includes various stages like haemostasis, inflammation, proliferation, and re-modelling. These stages work in an orchestrated manner to repair damaged tissue and restore function. Classic wound dressings for exuding wounds must remain in close contact with the wound and be non-adherent to the wound surface to prevent damage to the delicate wound healing layer. Furthermore, they must have optimum absorption capacity with excellent Moisture Vapour Transmission Rate (MVTR) to remove excess fluid and maintain a moist environment that promotes optimal healing.

The Benefits Of A Moist Wound Environment For Wound Healing

Exuding skin wounds are a major concern in health care. To address these wounds, moist wound healing has been practised since at least the seventh century (Paulus of Aegina). In 1850, Langenbeck used wet treatment for surgical wounds, and eight years later, Passavant reported on wet (immersion in a bathtub) treatment of burns. Like other tissues, skin tissue is capable of self-regeneration. However, different types of exuding wounds like diabetic wounds, second-degree burn wounds, bed sores, and large traumatic wounds fail to self-heal and require intervention in the form of wound dressings that accelerate the healing process. The benefits of a moist wound environment are multifaceted, leading to faster and more effective healing. Firstly, the absence of an eschar or dead tissue that forms over healthy skin, allows for quicker wound closure, saving time and energy. Secondly, the moist environment enables epithelial cells to migrate and re-epithelialize the wound more efficiently, as keratinocytes can rapidly cover the wound surface without the need to navigate through a dry crust. Moreover, the moist environment eliminates the need for forceful removal of dry dressings, thereby reducing pain for patients. Moist environment also facilitates effective nutrient transport for cells to proliferate and differentiate.

While a moist environment creates conditions conducive to microbial growth, yet surprisingly, wounds treated with moist dressings have been found to have lower infection rates compared to those treated with dry dressings. Overall, the use of moist dressings can significantly improve wound healing outcomes by reducing pain, promoting tissue regeneration, and limiting the risk of infection.

What Is Moisture Vapour Transmission In Wound Dressings And How Does It Promote Better Healing?

Moist wound dressings can be in the form of films, foams, hydrocolloid dressings, hydrogels, alginate dressings, and NPWT dressings. There is no one dressing that fits all wound types. Moreover, as the healing of a wound progresses and the amount of exudate decreases, one single dressing may not be optimal for the different phases of healing.

Table 1. Types of dressings, MVTR range and Examples.

The moist dressing’s ability to transmit water vapour, known as Moisture Vapour Transmission Rate (MVTR), is a crucial physical characteristic that enables effective wound healing. MVTR is the steady state at which water vapour permeates the dressing. It is measured using two methods: the desiccant method (ASTM E-96 Test) and the water method. In the desiccant method, a cup assembly is placed in a dry incubator with controlled temperature and airflow. Periodic manual weighing of the cup measures the amount of water lost over time, determining the MVTR. The test cups are placed upright for low moisture contact. [Fig 2.]

In the water method, a dish is filled with water and the dressing is sealed on top, then placed in an environment with low humidity. The amount of water vapour transferred from the dish during the test period is measured by weighing the dish.

To ensure accuracy and consistency, both methods are considered in the standard test method for MVTR, which takes into account the differences in results between the two procedures. For the desiccant method, the MVTRs of the dressings varies from 80 to 1620 g/m2/24 h.

The Moisture Vapour Transmission Rate (MVTR) of a wound dressing is a crucial factor in maintaining the optimal level of hydration for the wound. A dressing with very high MVTR leads to wound desiccation/drying while a very low MVTR will lead to complications like infection, maceration, etc. Therefore, finding a dressing with an optimal MVTR is essential to prevent desiccation or excessive fluid accumulation. For instance, an MVTR of 800 – 1000 g/m2/24h has been suggested to provide an adequate level of moisture without risking desiccation. However, different wounds require different levels of moisture management.

How Does Seriderm Provide An Optimal Moist Wound Healing Environment?

Seriderm/Seriderm Ag have an MVTR of 800 ± 100 g/m2/24 h to provide an optimal moist environment locally to promote wound healing.

Seriderm/Seriderm Ag is an advanced wound dressing completely made out of a natural polymer of Silk proteins. Seriderm is a non-adherent and absorbent silk protein-based dressing that offers optimal moisture management at the wound site by absorbing exudate and maintaining ideal moisture levels for faster healing. Additionally, Seriderm’s novel composition improves vasculature and granulation tissue formation. With these unique advantages, Seriderm promotes faster healing of a wide range of wounds, including chronic, non-healing wounds such as diabetic ulcers, second-degree burns, pressure ulcers, and surgical wounds. Additionally, Seriderm Ag combines the healing power of Seriderm with the antimicrobial action of Silver ions for management of infected wounds.

Seriderm dressing has a range of MVTR of 800-1000g/m2/24 h, which is suggested to provide an adequate level of moisture without risking desiccation. Our dressings have adequate absorptive capacity which can be applied to moderately exuding wounds.

Conclusion

Wound dressings play a crucial role in creating and maintaining a moist environment, essential for optimal wound healing. Seriderm/Seriderm Ag dressings have the ability to transmit water vapour, absorb excess fluid, and maintain antimicrobial properties. Additionally, these dressings have integrity and absorptive capacity that maximises their wear time by matching the wound’s fluid production to prevent accumulation of exudate or dehydration. This allows for a controlled moist environment that gives non-adherence, reduces pain during dressing changes, prevents scarring, and supports tissue growth and repair for better wound healing.

References

[1] Testing dressings and wound management materials S. T. THOMAS

[2] Nuutila K, Eriksson E. Moist Wound Healing with Commonly Available Dressings. Adv Wound Care (New Rochelle). 2021 Dec;10(12):685-698. doi: 10.1089/wound.2020.1232. Epub 2021 Feb 11. PMID: 32870777; PMCID: PMC8568799.

[3] Jones V, Grey JE, Harding KG. Wound dressings. BMJ. 2006 Apr 1;332(7544):777-80. doi: 10.1136/bmj.332.7544.777. PMID: 16575081; PMCID: PMC1420733.

[4] ASTM. 1986. “Standard Test Methods for Water Vapour Transmission of Materials.” Annual Book of ASTM Standards, 15(9):833-842.

[5] Zehrer CL, Holm D, Solfest SE, Walters SA. A comparison of the in vitro moisture vapour transmission rate and in vivo fluid-handling capacity of six adhesive foam dressings to a newly reformulated adhesive foam dressing. Int Wound J. 2014 Dec;11(6):681-90. doi: 10.1111/iwj.12030. Epub 2013 Jan 30. PMID: 23362795; PMCID: PMC7951035.

Author Bio – Jaya Verma is a Production Engineer at Serigen Mediproducts. She holds a B.Tech in Polymer Specialization from MIT-WPU, Pune and has 2 years of professional experience in the production of wound dressings.