This site uses cookies to track traffic & improve your experience. Click Accept to agree to our Privacy Policy

About Us

- Home

- About

- Our Story

Our Story

Serigen, formerly known as BiolMed Innovations, is an innovation-driven, tissue regeneration products company, founded with the vision to become a global leader in biomedical devices. We leverage the materials science of natural silk proteins to develop novel biomedical products that serve the clinical needs of diverse patient communities. A brainchild of passionate scientists and innovators, Serigen originated as a spin-off from CSIR-National Chemical Laboratory, an esteemed research institute specialising in materials and chemicals based in India.

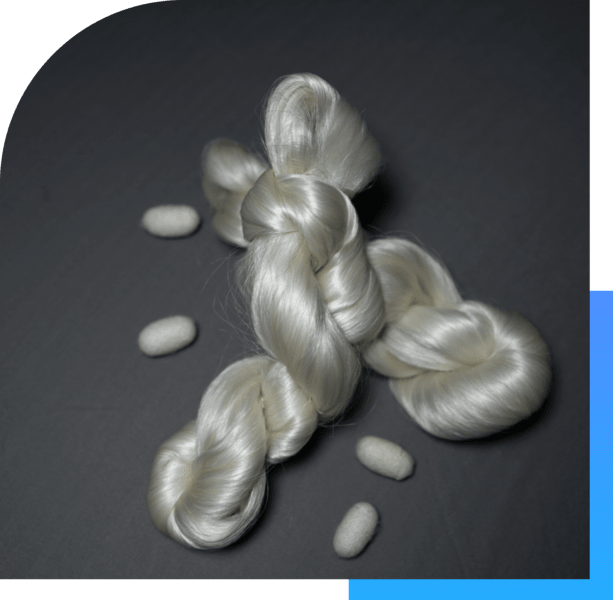

The name “Serigen” derives its inspiration from the Latin word “Seri,” which means “shiny” and serves as a synonymous term for “silk.” Silk is a fascinating natural material extracted from silkworm cocoons, with each cocoon containing a continuous thread that can span several kilometres.

The name “Serigen” derives its inspiration from the Latin word “Seri,” which means “shiny” and serves as a synonymous term for “silk.” Silk is a fascinating natural material extracted from silkworm cocoons, with each cocoon containing a continuous thread that can span several kilometres.

Silk, a luxurious and radiant fabric, has dominated the textile industry for centuries. Additionally, silk threads have been utilized for suturing wounds for many decades, boasting a long history of safe medical application.

While India currently relies on imports for over 80% of its medical devices used in the healthcare sector, it is noteworthy that sericulture, the practice of silk agriculture, is a well-established industry in the country. India ranks as the second-largest global producer of silkworm silk, and the sericulture sector employs more than 8.6 million individuals. Serigen’s inception stemmed from the vision of bridging these two sectors and leveraging the existing strengths of silk production in India to develop cutting-edge biomedical products.

While India currently relies on imports for over 80% of its medical devices used in the healthcare sector, it is noteworthy that sericulture, the practice of silk agriculture, is a well-established industry in the country. India ranks as the second-largest global producer of silkworm silk, and the sericulture sector employs more than 8.6 million individuals. Serigen’s inception stemmed from the vision of bridging these two sectors and leveraging the existing strengths of silk production in India to develop cutting-edge biomedical products.

Our Vision

To be recognised as a global leader in cutting-edge tissue regeneration products that cater to the unmet clinical needs of diverse patient communities with innovative biomaterial solutions

Our Mission

To invent, manufacture and provide clinician-trusted and world-leading next-gen tissue repair and augmentation products, especially based on natural polymer platforms, specifically silk proteins, to patients and healthcare systems globally.

Our Strengths

At Serigen, we have pioneered innovative processing protocols that transform silk threads into a solution that can be structured and shaped into various forms. The scientific advancements have been published in highly regarded international journals, and the technology has been safeguarded through patents granted in the United States, India, Europe, and Japan.

At Serigen, we have pioneered innovative processing protocols that transform silk threads into a solution that can be structured and shaped into various forms. The scientific advancements have been published in highly regarded international journals, and the technology has been safeguarded through patents granted in the United States, India, Europe, and Japan.

The team at Serigen comprises a diverse group of experts, including scientists, engineers, clinicians, serial entrepreneurs, and regulatory specialists. The co-founders of Serigen possess strong academic backgrounds and hail from renowned materials research institutes such as IITB, MIT, UDel, and CSIR-NCL. We bring extensive experience in the development of successful medical implants and biomaterials to our endeavours. Furthermore, we abide by the highest quality standards throughout each stage of product development, and our facility is ISO 13485 certified.

Leadership

Advisors

Our Proud Associations

Technology Partner

Our Proud Associations

Incubation Partner